Porcelain Stoneware Floor tiles

Refin’s collections: expressing design Made in Italy

Stylish and original porcelain tile collections, colours and combinations devised to astound and to tile today’s Design settings. Ceramiche Refin’s tiles are a contemporary and highly topical expression of the vitality and creativity of excellence “Made in Italy”.

Indoor and outdoor floor tiles

The floor is the calling card for any setting, so the choice of tiles should be made with the utmost care. From the age of antiquity, floors in Italian homes have been called upon to represent the sophistication of the home owner. As the centuries went by, the mosaic floors typical of ancient Rome were replaced by various types of floor tiles, right up to porcelain stoneware. Tiles oozing style Made in Italy which are currently used across the globe on the floors of the most prestigious hotels, stores and offices.

Tiles can be used in indoor and outdoor settings. However, outdoor use requires certain specific properties: resistance to the weather, to heat and to cold. Indoor floor tiles are less in need of these technical aspects.

Depending on whether they are used in a residential or a commercial setting, tiles need to meet various requirements. For commercial spaces, slip-resistance and durability under conditions of high foot traffic are required. In the case of products designed for domestic settings, such as bathroom tiles, kitchen tiles and living room floor tiles, the evaluations are also of an aesthetic nature.

Porcelain stoneware for floors

Why is it important to have porcelain stoneware floor tiles?

Porcelain stoneware is a particular type of ceramic tile with a water absorption coefficient of less than 0.5%. Its physical and chemical properties make it a unique material: it has an extremely low level of porosity and is impermeable, frost-proof and is resistant to abrasions and sudden changes in temperature. It therefore proves to be suitable for use in places that feature extremely accentuated variations in temperature.

Owing to these features, which it retains over time, porcelain stoneware is used in outdoor settings and in high-frequency venues, places where detergents need to be used without damaging the floor tiling. Indeed, it can be treated with acidic based detergents, and it is especially stain-resistant since it is impermeable. Easy to clean, it requires minimal maintenance and is much easier to handle than other materials.

The industrial processing of porcelain stoneware has evolved to such an extent that we have achieved the production of large-size slabs, the ideal application of which is on floors in public buildings.

The versatility of the material makes stoneware suitable for any area in the home, from the kitchen through to the bathroom. However, domestic settings require a particular focus on aesthetic styling: the floors of a home need above all to be beautiful.

This need has led to the production of porcelain stoneware tiles that reproduce the appearance of multiple materials, such as wood, marble, and stone. Slabs that rouse the same feelings as the material they imitate and allow the existence in the comfort of your own home of the appeal, for instance, of a parquet floor, yet with all the advantages of stoneware.

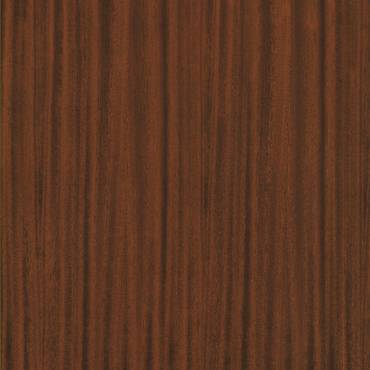

Wood-look porcelain stoneware

Wood look tiles: often found in Italian homes, parquet floors convey feelings of warmth and intimacy. Despite the enjoyable visual effect, wooden floors have features that sometimes make their maintenance difficult. Wood-look porcelain stoneware is the perfect option to recreate the look of a parquet floor while benefiting from the hard-wearing resistance and reliability of stoneware.

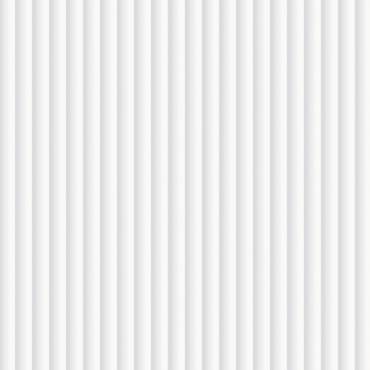

Brick-look stoneware tiles

Brick-look tiles are especially versatile, suitable for both flooring and wall tiling in domestic and commercial settings alike. Brick-look stoneware offers endless solutions outdoors too, from garden paths to decorative features on the façades of private and public buildings.

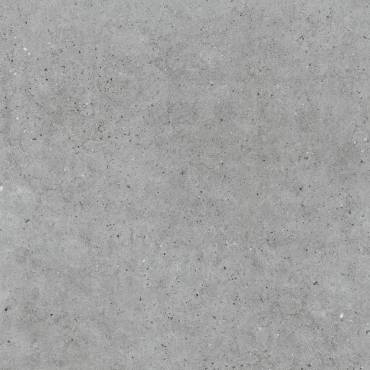

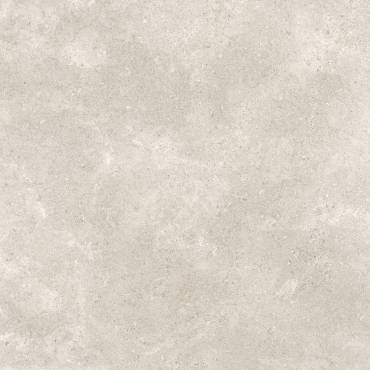

Stone-look stoneware tiles

One of the materials whose styling qualities porcelain stoneware replicates is natural stone. The Refin product range includes multiple collections in porcelain stoneware with the appearance of natural stone, each one inspired by materials with different origins and characteristics, but which share elegance and character. Values which – teamed with the technical performance of stoneware – create balanced products with a contemporary taste, to be used in elegant indoor and outdoor floors and wall tiling.

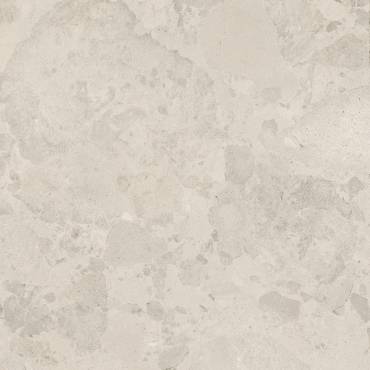

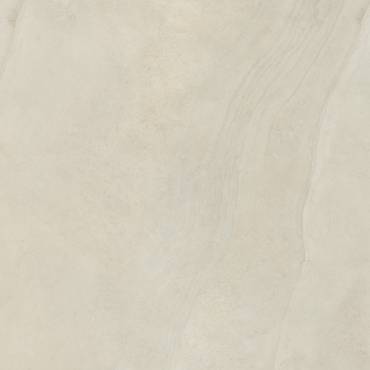

Travertine-look stoneware tiles

The eclectic nature of travertine is brought back to life in porcelain stoneware. Travertine-look tiles combined the elegance of stone with the hard-wearing resistance of this exceptional ceramic tile to accommodate all possible interior décor needs. Slabs, which are also produced in large sizes, express a classical style that has been restyled with a modern twist.

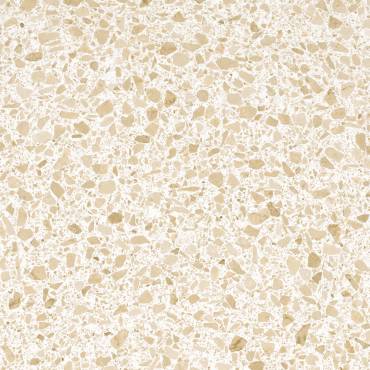

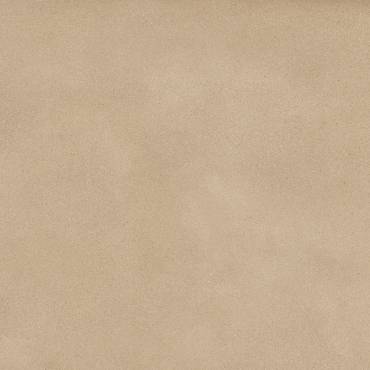

Terracotta-look stoneware tiles

The evocative power of terracotta and the practicality of new ceramic tiles are at the heart of Refin’s Bricklane collection, which draws its inspiration from the namesake metropolitan area in London. Porcelain stoneware slabs with innovative surfaces that replicate the typical textures and colours of terracotta with a modern twist, while retaining features of continuity with the past.

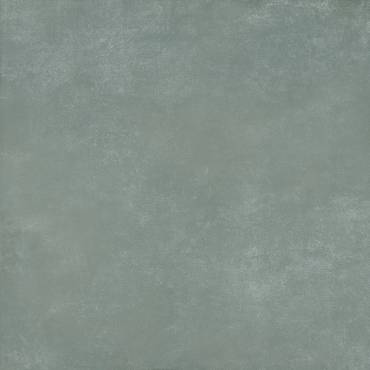

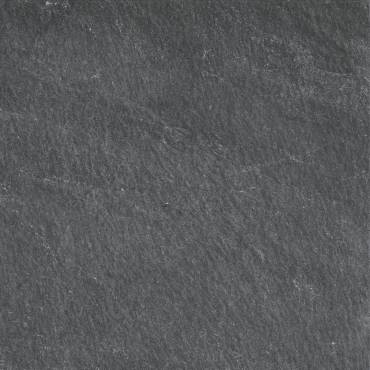

Slate-look stoneware tiles

The textured strength of slate injects life into the Wide collection. A modern product, which is ideal for large development projects in venues with high foot traffic, includes tiles in the OUT2.0 version and in large sizes. Refin’s slate-look tiles reproduce the essence of this stone to put together floor tiles that lend a touch of sophistication and depth to their surroundings.

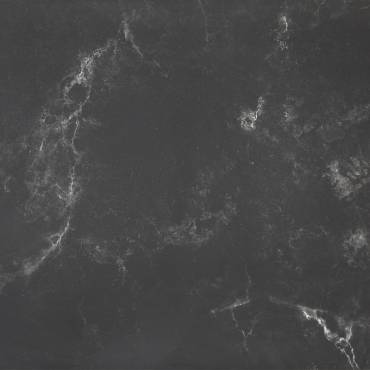

Marble-look stoneware tiles

The sophisticated charm of marble is renovated with Refin’s stylish marble-look tiles. The products in the Prestigio collection will enhance any setting, and they are available in multiple colours and sizes (including large sizes 120×278 cm, 120×120 cm and 120×240 cm).